I recently had the opportunity to test out Samson Manufacturing's new SX rail series. Many of you are familiar with their Evolution (EVO) line of rails, as they have been a mainstay of Samson's lineup for several years. What brought about the SX line was a desire to begin production of an M-LOK handguard. Originally, Samson tried to build an M-LOK version of their EVO, but Magpul rejected the design because it lacked the required flats behind the slots. Those flats allow the M-LOK T-nut to properly seat, and Magpul was concerned that the rounded shape of the EVO would conflict with good accessory mounting.

The resulting redesign is the SX series. While a significant departure from the EVO, I'm very impressed with this rail. Feeling significantly slimmer than the EVO, it delivers a solid performance, and it looks good doing it. I've been running a 15" version on my 9mm Colt-pattern pistol caliber carbine for about a month now, and it's gotten attention every time I've been to the range.

A couple of differences between the SX and the EVO to note:

1) the inner diameter is smaller, coming in at 1.3" in diameter, as opposed to the EVO's 1.56",

2) it uses a proprietary barrel nut instead of the adapter plate of the EVO, and

3) it has an integrated QD at the receiver end.

With the history covered, let's focus on the SX.

Installation was simple. The supplied barrel nut wrench interfaced flawlessly with the nut and my 1/2" drive torque wrench. Before attempting to slide the rail over the nut, I made sure to fully tighten the bias block at the top of the rail, and loosen the two screws at the bottom.

|

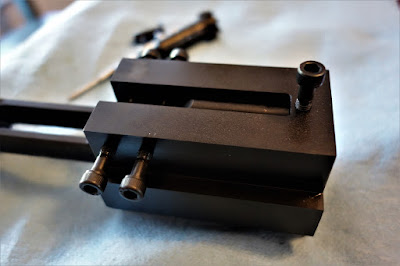

| The proprietary barrel nut. Note the knurled surface and the wide groove that provides purchase for the clamp. |

NOTE: If you are installing this rail over a low-pro gas block, you may need to remove the bias block before sliding the rail over the gas block, then re-install.

The rail does fit very snug on the nut. I personally had no issues sliding it on with my hands, but I have heard that they occasionally need a light tap with a nylon hammer. Not really a problem to me, as that indicates a solid fit, but just a heads up. Once the rail is seated against the receiver and aligned, tighten the two bottom screws down to the torque spec of 60 in-lbs. To ensure alignment, I used an A2 carry handle to hold the rail in place while I torqued the screws. The fit between the upper receiver and the top Picatinny rail was perfect on my Colt. That's been rare, at least in my experience. Usually there is at least a mild mismatch between the rail of the receiver and the rail of the handguard.

|

| Using a carrying handle to ensure alignment between the upper and handguard |

|

| The bottom screws that set the clamp. Torque spec is 60 in-lbs. |

Now, having worked with a lot of rails that clamp around the circumference of the nut or screw into the nut, the levered clamp design of the SX looked a little strange to me. I'll freely admit that I had my doubts on its ability to stay put when strain was added. So, I strained it. And I put some real effort into it, particularly in an attempt to pull it free of the nut. It didn't budge. I tried rotating it, just to see if I could get it to wiggle inside the anti-rotation tabs. No movement whatsoever. The clamp interface between the rail and barrel nut proved itself remarkably solid, probably assisted by the knurled surface of the barrel nut and the general tight fit. I've mounted accessories from both Impact Weapons Components and Magpul, and gotten solid lockup in the slots as well.

Overall, I think this is a rail you should take a serious look at if you're in the market. It's got great aesthetics and solid performance. My only "meh" was the rear QD mount, as I almost never use them, regardless of rail manufacturer. That had nothing to do with the mount itself, just my personal setup preferences. They do make their SXS rail without the rear QD, so consider that if you don't feel like you need the QD. No matter if you go with the SX or SXS, you won't be disappointed.

Check out the SX family at http://www.samson-mfg.com/category/SX.html